- WhatsApp: 8613777772066

- Email: [email protected]

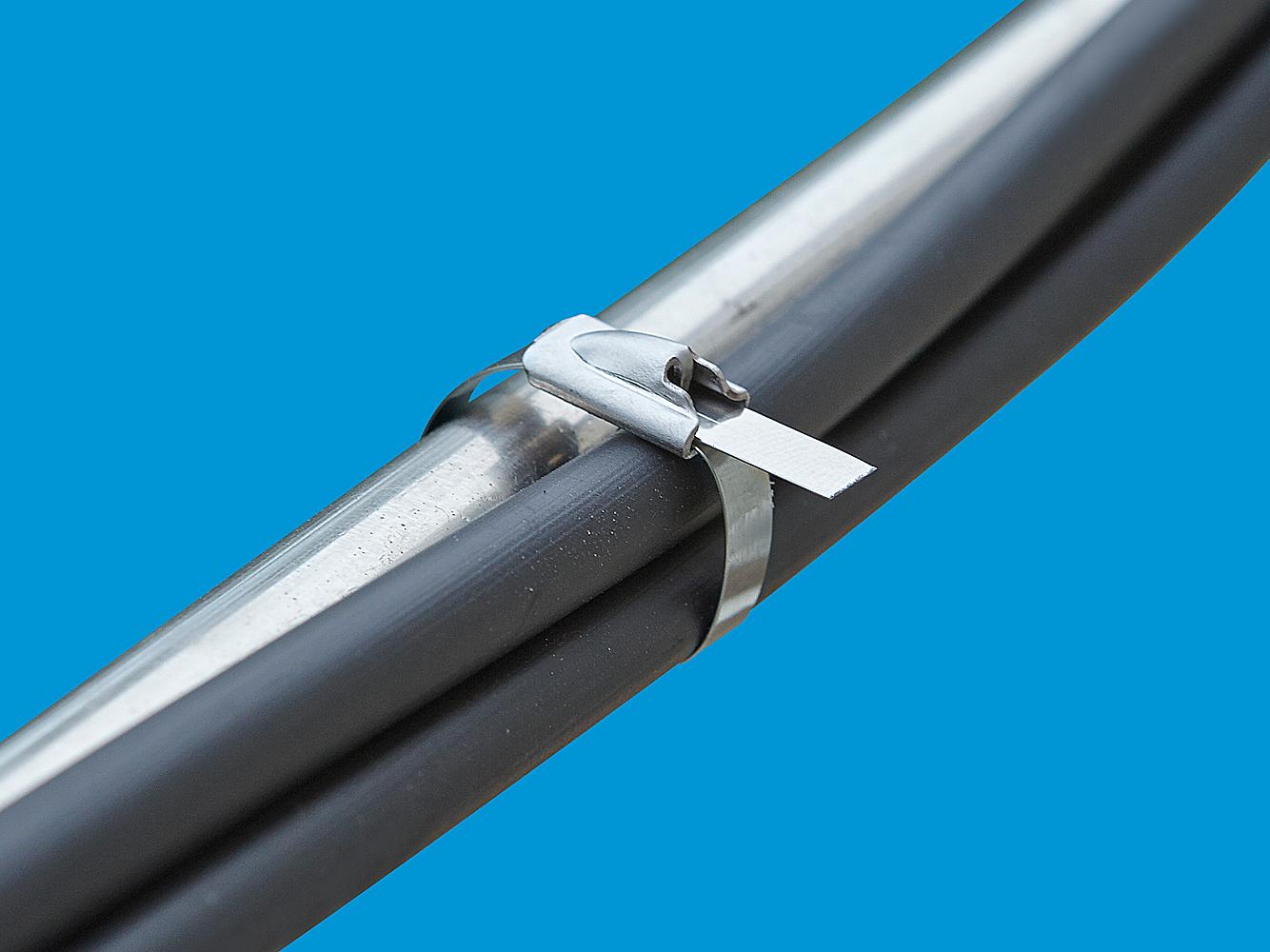

Steel cable ties are essential devices for securing and organizing different objects, specifically in settings where stamina and durability are important. As a specialist in this field, I’ll assist you with the appropriate use of steel cable ties based on my extensive experience.

Prior to making use of metal cable ties, gather the required devices: the steel cable ties themselves, a pair of pliers, and a cutter. Ensure the surfaces and products to be connected are clean and completely dry to guarantee a safe fit.

Source: Amazon

Steel cable ties are essential devices for securing and organizing different objects, specifically in settings where stamina and durability are important. As a specialist in this field, I’ll assist you with the appropriate use of steel cable ties based on my extensive experience.

Prior to making use of metal cable ties, gather the required devices: the steel cable ties themselves, a pair of pliers, and a cutter. Ensure the surfaces and products to be connected are clean and completely dry to guarantee a safe fit.

To make use of metal cable ties efficiently, adhere to these steps:

To tighten up the steel cable tie:

When the metal cable tie is safe, removed the excess tail for a tidy finish:

Metal cable ties are specifically useful in numerous settings:

| Application | Advantages |

| Industrial settings | High resilience and resistance to severe problems |

| Building websites | Strong hold for sturdy tasks |

| Marine applications | Resistance to rust and saltwater |

Recognizing the correct use steel cable ties ensures they execute successfully and securely for your demands.

Steel cable ties are highly functional and sturdy, making them ideal for a vast variety of applications. You ought to think about making use of metal wire ties in environments where high stamina and resistance to extreme problems are necessary. These ties are particularly useful in commercial settings, such as in construction, production, and energy setups, where they can firmly hold hefty or crucial parts with each other.

Among the primary advantages of metal wire ties is their capacity to stand up to rough environments. They are resistant to extreme temperature levels, UV radiation, chemicals, and corrosion, making them optimal for exterior applications and areas with serious weather condition problems. For example, they are typically made use of in maritime atmospheres, oil and gas industries, and other fields where traditional plastic ties would fall short.

In enhancement, metal cable ties are essential in scenarios where fire security is a worry. Unlike plastic ties, metal ties do not melt or produce hazardous fumes when subjected to high temperature levels. This particular makes them appropriate for use in fire-prone areas, such as in electric installments within structures, aircraft, and vehicles.

Furthermore, metal cable ties are vital in safeguarding durable items or bundles of cables that need a durable and reliable securing service. They offer exceptional tensile strength compared to their plastic counterparts, making them excellent for protecting large packages of cables, pipelines, or various other hefty items in commercial and industrial setups.

When carrying out upkeep or repairs, steel wire ties are also helpful because of their reusability. Numerous metal cable ties can be quickly unlocked and recycled, which is both cost-efficient and eco-friendly. This function is specifically beneficial in applications where regular modifications or disassembly are necessary.

In summary, you must select metal cable ties in situations that demand high durability, resistance to extreme problems, fire safety and security, and the safeguarding of durable materials. Their robust nature and flexibility make them an essential tool in a variety of demanding environments.

Source: ULINE

Steel wire ties are highly effective for protecting and packing products as a result of their strong and durable layout. They work based on an easy yet robust system that makes sure a limited and protected hold. The core parts of metal cable ties consist of the steel strip and a locking mechanism.

The steel strip is typically made from stainless-steel, which offers superb resistance to corrosion, extreme temperature levels, and UV radiation. This makes them appropriate for both interior and outdoor applications. The strip has a collection of ridges or teeth along its size that interact with the locking mechanism.

The securing mechanism is an essential component of just how metal cable ties function. It is generally located at one end of the tie and contains a tiny steel tab or round bearing that engages with the teeth on the strip. This interaction ensures that as soon as the tie is tightened, it can not be conveniently loosened, supplying a secure hold.

| Part | Function |

| Metal Strip | Gives strength and resilience, with teeth for securing |

| Locking Device | Engages with the teeth to safeguard the tie |

When the steel cable tie is wrapped around an item, the totally free end is threaded with the locking system. As it is pulled tight, the teeth on the strip engage with the locking tab or sphere bearing, stopping the tie from slipping. This easy yet reliable style enables quick and protected packing of cable ties, pipelines, or other products.

Among the main benefits of steel cable ties over their plastic counterparts is their exceptional toughness and sturdiness. They can stand up to harsh ecological conditions, including high warm, cool, and direct exposure to chemicals. This makes them perfect for usage in commercial, aquatic, and building and construction settings.

Furthermore, metal wire ties provide a higher tensile strength, which implies they can hold heavier lots without breaking. This is specifically essential in applications where security and reliability are critical, such as in electrical installments or durable packing jobs.

In general, the performance of steel cable ties is an outcome of their robust building and reputable securing device, making sure that they continue to be safe even under challenging conditions.

To properly tighten steel cable ties, it is crucial to follow an organized strategy to ensure a protected and reliable attachment. Right here are the actions to properly tighten steel cable ties:

Making use of suitable devices is vital for tightening up metal cable ties. Typically, a specialized tensioning tool designed for metal ties is recommended. These tools aid apply a regular tension, making sure the tie is neither also loose nor too tight.

Before beginning, make sure that the surface or bundle you are protecting is clean and without particles. This assists in attaining a tight and protected fit.

Begin by threading the tail end of the metal cable tie through the securing device. Pull the tie limited by hand to get rid of any kind of slack, ensuring it is snug around the object.

Place the nose of the tensioning device over the tail of the tie. Press the manage of the tool to gradually tighten up the tie. The device will usually have a mechanism to regulate the tension used, allowing you to accomplish the wanted tightness.

In circumstances where a tensioning device is not readily available, you can tighten up the metal wire tie by hand. Draw the tail end firmly while holding the tie in place. Beware to prevent over-tightening, which can damage the tie or the packed objects.

Once the metal cable tie is tight, make use of the reducing blade of the tensioning tool or a separate cutting tool to trim off the excess tail. Guarantee the cut is tidy to stay clear of any sharp sides that could position a safety and security hazard.

After tightening and cutting, examine the tie to ensure it is safe and secure and there are no sharp sides. If the tie appears loosened or harmed, change it and repeat the process to assure a protected attachment.

Source: AliExpress

Reducing metal cable ties needs accuracy and the right tools to make certain safety and security and performance. Unlike plastic cable ties, steel ties are a lot more durable and usually used in environments where toughness and resilience are critical. Here are the steps and considerations for cutting metal cable ties:

To safely cut metal cable ties, you will need the complying with tools:

| Device | Description |

| Diagonal Pliers | Sharp pliers that can puncture metal ties cleanly. |

| Cable Cutters | Made to handle steel cable, these are likewise reliable for cutting metal ties. |

| Bolt Cutters | For thicker or even more sturdy steel ties, bolt cutters offer the needed leverage and power. |

Before you start, guarantee you are using shatterproof glass and gloves to secure on your own from any type of steel shards or sharp edges. Metal wire ties can develop sharp points when reduced, which can create injuries.

Area the cutting device around the metal cable tie as near to the locking device as possible. This will guarantee that you removed the excess length without endangering the tie’s grasp.

Firmly squeeze the deals with of the cutting device. For angled pliers or cable cutters, a single, solid capture ought to suffice. For screw cutters, you may need to apply more pressure. Ensure the cut is tidy to prevent leaving sharp edges or burrs.

When the cut is made, check the end of the tie. If there are any type of sharp sides, think about making use of a file or sandpaper to smooth them down. This will prevent injury and make sure the tie does not snag on anything.

Properly take care of the cut pieces of metal tie. They can be sharp and possibly dangerous, so area them in a container to avoid unintended injury or damage.

Here are some added ideas to remember when reducing metal cable ties:

| Pointer | Explanation |

| Use the Right Tool | Always pick a tool designed for cutting metal to make sure a tidy cut and reduce the threat of injury. |

| Cut at an Angle | Cutting at a mild angle can aid minimize the sharpness of the cut edge. |

| Check for Burrs | After reducing, constantly look for and get rid of any type of burrs to stop injury. |

Removing steel cable ties calls for cautious focus to prevent harming the surrounding materials or harming yourself. Here are the actions and techniques to successfully remove them:

One of the most typical approach to eliminate steel cable ties is by using cutting devices such as diagonal pliers, wire cutters, or a specialized wire tie removal tool. Placement the cutting tool as near the securing mechanism as possible. This assists guarantee that you cut via the metal tie cleanly and minimizes the danger of leaving sharp sides that can create injury or damages.

Constantly use protective gloves and shatterproof glass when cutting metal wire ties. The cut sides can be sharp and may spring back when tension is released, presenting a risk of cuts or eye injuries. Furthermore, make certain that the location around the tie is free from other cables or products that can be accidentally damaged during the reducing process.

In scenarios where cutting the tie is not viable or could trigger damages, an alternative approach entails using a flat-head screwdriver to carefully pry open the locking device. Place the screwdriver suggestion into the locking mechanism and gently spin to release the tie. This technique needs more accuracy and perseverance but can be reliable for recyclable ties or in fragile atmospheres.

Once the metal cable tie is gotten rid of, check the location for any kind of remaining sharp sides or prospective threats. If any kind of sharp edges are present, use a file or sandpaper to smooth them out. Properly deal with the gotten rid of ties to stop any kind of unintended injuries.

Source: Boese Electronic Plastic

Installing metal cable ties is a straightforward process, but it needs interest to detail to make sure a safe and efficient hold. Here is an extensive guide on the proper setup of metal cable ties:

Adhere to these actions to set up steel cable ties appropriately:

| Step | Description |

| 1 | Prepare the materials: Collect your steel cable ties, an appropriate cutting device, and any type of various other essential tools. Ensure the ties are the proper size for the cables or objects you are packing. |

| 2 | Position the tie: Wrap the steel cable tie around the item or bundle of cables. See to it the tie is located correctly, with the locking device accessible and the tie level against the surface area. |

| 3 | Insert the tail: Thread the tail of the tie via the locking mechanism. Pull it with until it begins to tighten up around the bundle. |

| 4 | Tighten the tie: Draw the tail of the tie strongly to tighten it around the object. For a more protected fit, use a specialized tensioning device created for metal cable ties. |

| 5 | Trim the extra: Once the tie is safely tightened, use a reducing tool to cut the excess tail. Beware to prevent damaging the lock or the packed cables throughout this process. |

Throughout installation, you may experience some typical issues. Below are a few pointers to address them:

For the very best results when mounting metal cable ties, consider the following pointers:

When identifying the spacing for steel cable ties, it is necessary to take into consideration both the kind of application and the particular requirements of the job. Appropriate spacing guarantees the stability and safety and security of the packed cables or elements, avoiding sagging, motion, or potential damages.

Numerous variables influence just how far apart metal wire ties should be put:

While there is no one-size-fits-all response, general standards can be followed for typical applications:

| Application Type | Advised Spacing |

| Lightweight Cables | 12-18 inches (30-45 cm) |

| Medium-Weight Cable Ties | 6-12 inches (15-30 centimeters) |

| Heavy-Duty Cable Ties | 3-6 inches (7.5-15 centimeters) |

| High-Vibration Environments | 3-6 inches (7.5-15 cm) |

These ranges can give a basic framework, but certain project needs and market standards need to constantly be spoken with. As an example, the National Electrical Code (NEC) or other pertinent criteria could determine particular spacing needs for electrical setups.

To ensure ideal efficiency of steel cable ties:

By adhering to these guidelines and taking into consideration the certain requirements of your task, you can guarantee that your steel cable ties give reputable and durable support.

Metal cable ties function based on a simple yet robust mechanism that involves a metal strip with teeth and a locking mechanism. When the tie is wrapped around an object and tightened, the teeth on the strip engage with the locking tab, securing the tie in place.

Metal cable ties are ideal for environments that require high strength, durability, resistance to extreme conditions, and fire safety. They are commonly used in industrial, construction, and marine applications due to their superior tensile strength and reliability.

To tighten metal cable ties effectively, use the correct tools, thread the tie properly, and apply the right amount of tension. Hand-tightening and using pliers for a secure fit are recommended steps to ensure the tie is snug and not prone to slipping.

To cut metal cable ties safely and effectively, you will need tools such as diagonal pliers, wire cutters, or bolt cutters. These tools are designed to handle metal ties cleanly and efficiently.

To remove metal cable ties, you can use cutting tools like pliers or wire cutters. Alternatively, you can carefully pry open the locking mechanism with a screwdriver. Always wear protective gear and ensure the area is clear of any potential hazards.

The spacing of metal cable ties depends on factors like cable weight, environmental conditions, application type, and load distribution. Recommended spacing distances vary for lightweight, medium-weight, and heavy-duty cables to ensure proper support and security.

Privacy Policy | Sitemap

Copyright BOESE Co.,Ltd