- WhatsApp: 8613777772066

- Email: [email protected]

Cable ties are a very common tool for bundling and binding. They have a simple structure, are compact in size, and are easy to use. They provide a secure and efficient bundling solution, making them widely used in various industries and in our daily lives. This article will explore the differences between stainless steel cable ties and nylon cable ties from multiple angles.

There are two main types of cable ties on the market: stainless steel cable ties and nylon cable ties. They are both used for bundling, and the choice of which material to use depends on the specific application and the items being tied. Each material has different performance characteristics.

Corrosion Resistance: Stainless steel can withstand harsh environments and resist various chemicals, maintaining strong binding performance.

High-Temperature Resistance: Stainless steel not only resists corrosion but also performs well at higher temperatures, withstanding significant temperature differences.

High Strength: Compared to nylon, stainless steel ties have greater strength and can bear higher tension, making them suitable for securing heavy items.

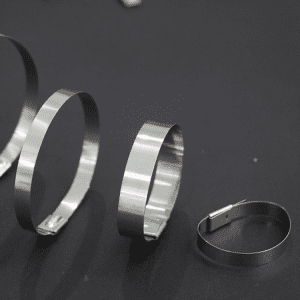

Stainless Steel cable ties

Lightweight: Nylon plastic is lightweight and flexible, making it easy to carry and transport.

Cost-Effective: Generally, nylon is much cheaper than stainless steel, making nylon ties a budget-friendly option.

Variety of Colors: Nylon ties come in many colors, allowing users to bind different items easily and helping with organization and identification.

Nylon Cable Tie

When choosing cable ties, it is important to consider the specific application and desired results. Stainless steel and nylon cable ties differ in durability and longevity due to their material properties. Generally, stainless steel ties are more durable and have a longer lifespan than nylon ties, as they can withstand greater tension. Unlike nylon ties, stainless steel ties are less affected by UV rays, humidity, and chemicals, offering better durability and longevity.

Stainless steel cable ties are made from 304 or 316 stainless steel, which gives them a much higher tensile strength and load-bearing capacity compared to nylon ties. Depending on their width and thickness, the tensile strength that stainless steel ties can withstand varies. Here are the specifications for some popular stainless steel cable ties:

| Width(mm) | Thickness(mm) | Min.Tensile Strength(N) |

| 4.6 | 0.25 | 1100 |

| 7.9 | 0.35 | 1200 |

| 10 | 0.3 | 1700 |

| 12 | 0.3-0.35 | 2200 |

| 16 | 0.3-0.35 | 3400 |

In contrast, nylon cable ties are typically made from polyethylene (PE) and can withstand a tensile force ranging from about 100 to 1000 N, which is significantly lower than the load-bearing capacity of stainless steel ties. Therefore, tensile strength is an important factor to consider when choosing cable ties.

Stainless steel cable ties typically feature a metal locking design, allowing for easy binding and unbinding, which means they can be reused multiple times. This characteristic makes them very useful in applications where frequent tying and releasing are needed, such as temporary fixes during manufacturing or on equipment that requires regular maintenance. In terms of cost-effectiveness, while the initial price of stainless steel ties may be higher than nylon ties, their reusability and high strength can lead to lower overall costs over time. Additionally, the high strength and corrosion resistance of stainless steel ties reduce the frequency of replacements, further lowering long-term costs.

Nylon cable ties are generally difficult to fully unbind after use, so they are usually considered single-use products. Even if someone manages to unbind them, their performance cannot be guaranteed for later use. Some high-quality nylon ties do have reusable locking designs, but these are less common than those found in stainless steel ties. Regarding usage costs, nylon ties are well-suited for one-time applications or projects with tight budgets. They are often used for temporary binding or in situations where long-term holding is not required, making their low-cost advantage more apparent in these cases.

Stainless steel cable ties generally cannot be installed by hand; they require specific installation tools for proper securing. In contrast, nylon cable ties can be easily installed by hand, making them simple to use. Stainless steel ties have excellent corrosion resistance and durability, which means they require less frequent maintenance. On the other hand, nylon ties may need to be checked and replaced more often to ensure their binding performance remains effective.

Boese Electric Company was established in 2006 and is a modern enterprise that integrates research, production, sales, and service. It serves over 100 countries and more than 2,000 customers, with excellent quality ensuring a strong reputation. Its products have received ISO 9001, ROHS, TUV product certification, and CE certification. Boese’s cable ties are known for their reliability, strength, and durability. Here are some features of Boese cable ties:

Material: Made from high-quality 304 or 316 stainless steel, ensuring product durability from the raw material stage.

Tensile Strength: Boese offers various specifications of ties, with tensile strengths ranging from 1100 N to 3400 N, meeting different environmental and load requirements.

Corrosion Resistance: The high-quality 304 or 316 stainless steel provides excellent corrosion resistance, allowing Boese stainless steel ties to maintain strong binding performance even in marine environments.

High-Temperature Resistance: Compared to nylon ties, stainless steel ties can withstand high temperatures, making them suitable for various industrial applications.

High Strength: The average tensile strength is typically between 80 N and 100 N.

Durability: They are wear-resistant, tear-resistant, and corrosion-resistant, allowing for long-term use.

Cost-Effective: They have a long lifespan and offer good value for money.

Ease of Use: They are lightweight and can be carried easily, requiring no additional tools for installation, making them simple to operate.

Both stainless steel and nylon cable ties have their unique advantages and characteristics, allowing them to excel in different fields and environments. Depending on your specific needs, the choice of cable tie will vary. If you are looking for high-quality, durable, and reliable cable tie solutions, please visit Boese’s official website at https://www.boeseplastic.com. By choosing Boese ties, you will benefit from a globally recognized product, along with tailored solutions to meet your diverse requirements.

Privacy Policy | Sitemap

Copyright BOESE Co.,Ltd SUPPORT BY :JUNJ