- WhatsApp: 8613777772066

- Email: [email protected]

When choosing stainless steel cable ties, the first thing to consider is the material. Cable ties made from different materials will have different performances. There are two main types of Materials of Stainless Steel Cable Ties on the market:

Grade 304 stainless steel: This is the most commonly used stainless steel cable tie material, with good corrosion resistance and oxidation resistance, very suitable for electrical installation, high temperature pipe fixing and indoor fixing, etc.

Grade 316 stainless steel: This type of stainless steel cable tie has better corrosion resistance and chemical properties and is very suitable for marine environments, chemical environments and food processing industries.

If your tying location is constantly exposed to salt water, humid environments and chemical environments, it is recommended that you give priority to Grade 316 Stainless Steel to ensure a good fastening effect.

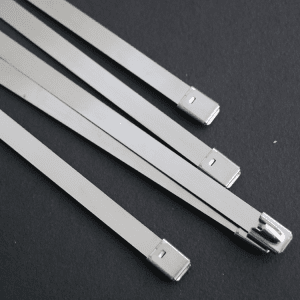

Best Price Stainless Steel Cable Ties

When choosing metal zip ties, you also need to consider their type. There are several different types of stainless steel metal cable ties on the market, each with different advantages and characteristics. The following are several common types:

Standard Cable Ties: This is the most basic type of Metal zip tie, suitable for most general applications, and can achieve fast and efficient bundling.

Releasable Cable Ties: This type of stainless steel cable tie generally has a release mechanism that can be adjusted or removed without destroying the binding performance of the cable tie, so it can be reused. Therefore, it is generally used for maintenance, transportation and testing.

Self-Locking Cable Ties: As the name suggests, this cable tie can be locked automatically when tightened by a unique locking mechanism. This cable tie can be locked without the use of a steel cable tie tool.

Heavy Duty Ties: This type of tie is generally wider to withstand higher tension. It is generally used for bundling heavy loads or large mechanical equipment. Installation of this type of cable tie generally requires the use of a Cable tie gun for stainless steel ties.

PVC Coated Stainless Steel Cable Ties: This type of stainless steel zip tie is covered with a layer of PVC protective coating on its surface, which provides additional protection for the zip tie, making the zip tie thicker and softer, and also protecting the cable from damage by the metal edge of the zip tie. It is generally used in communications, transmission and other scenarios with higher security.

Therefore, when choosing a stainless steel cable tie, you need to choose the type of stainless steel cable tie according to the scenario and industry you are using.

The correct selection of cable tie size and tensile strength is the key factor in ensuring the bundling performance of your stainless cable ties.

The length and width of the cable tie will directly affect the tensile strength of the cable tie. Using the stainless steel cable ties manufactured by Boese company as an example, we can help you select the correct cable tie by providing the relationship between several common sizes and tensile strengths, as shown in the table below:

| Width(mm) | Length(mm) | Max.Bundle Dia(mm) | Min.Tensile Strength(N) |

| 4.6 | 100 | 36 | 1100 |

| 4.6 | 300 | 76 | 1100 |

| 10 | 300 | 76 | 1700 |

| 12 | 350 | 78 | 2200 |

| 16 | 350 | 78 | 3400 |

Therefore, when choosing stainless steel cable ties, you need to choose according to your actual application scenario. For example, if the cable ties will be subjected to vibration or impact during use, it is recommended to choose cable ties with wider width and higher tensile strength.

When purchasing cable ties metal, you also need to understand the temperature changes in your application environment. Although stainless steel cable ties have good heat resistance, some ties may not meet your bundling requirements if exposed to extreme temperatures. Therefore, it is recommended that you choose Grade 316 Stainless Steel.

When purchasing stainless steel cable ties, the method of installation is also a factor to consider.Currently, except for some stainless steel cable ties with self-locking function that can be tightened manually, the installation of other stainless steel cable ties usually requires the use of a specific stainless steel ties gun. Therefore, if the stainless steel cable ties are used indoors and in an environment without vibration and impact, it is recommended to purchase Self-Locking Cable Ties, which is not only convenient for installation, but also saves the cost of purchasing stainless steel ties guns.

Cable Tie Gun Fastening Cable Tie Tool

In the eyes of many buyers, the purchase price of metal cable ties is more expensive than that of nylon cable ties. For example, when comparing Boese’s 10mm wide, 300mm long metal cable ties, the price of a Metal zip tie may be about ten times that of nylon cable ties.However, Metal zip tie is used in extreme application environments, requiring cable ties to provide long-term and strong binding effects, which nylon cable ties cannot achieve and need to be replaced frequently.Therefore, for harsh application environments such as high temperature, chemical corrosion, seawater corrosion, shock vibration and other scenarios, it is recommended to purchase stainless steel cable ties, which can save you a lot of money.

You may wonder? Do I need to consider the brand when choosing Metal zip tie? Absolutely. Good brands usually provide more reliable and better quality products. By understanding the brand’s history, product certification and customer feedback, we can better choose reliable Metal zip tie. For example, if you are from the European Union, you need to pay attention to whether the product has CE certification. If you are from the United States, you need to pay attention to whether it has UL certification, etc. Therefore, when purchasing, it is recommended to learn more about the brand and certification of the product.

Q:How to use metal cable ties?

A:First, you need to choose the appropriate type of metal cable ties, then wrap the metal cable ties around a fixed position, and use the metal cable ties gun to tighten it after adjusting the position. Finally, use the stainless steel cable tie cutting tool to trim off the excess cable ties and grind the edges to make them smooth.

Q: Can stainless steel cable ties be reused?

A: Generally speaking, standard stainless steel cable ties are not reusable. They are designed for one-time use. However, there are some types of stainless steel cable ties that are reusable, such as Releasable Stainless Steel Cable Ties, Heavy-duty Stainless Steel Cable Ties with Locking Mechanism, and Reusable Stainless Steel Cable Ties with Reusable Pins.

Q:What are the Stainless Steel Cable Ties called?

A:They have many names, such as metal cable ties, hose clamps, Stainless hose clamps, SS cable tie, Stainless steel tie wraps, Stainless steel zip tie, Cable ties stainless steel, radiator clamps, Metallic cable ties, Stainless steel cable zip ties and Heat resistant cable ties.

Choosing the right stainless steel cable ties requires us to consider many aspects such as raw materials, size, tensile strength, installation, cost, application scenarios and brands. Each factor will affect the actual application. Through the introduction of this blog, you can clearly understand how to choose stainless steel cable ties. Finally, I hope you can choose a satisfactory stainless steel cable tie.

Privacy Policy | Sitemap

Copyright BOESE Co.,Ltd