- WhatsApp: 8613777772066

- Email: [email protected]

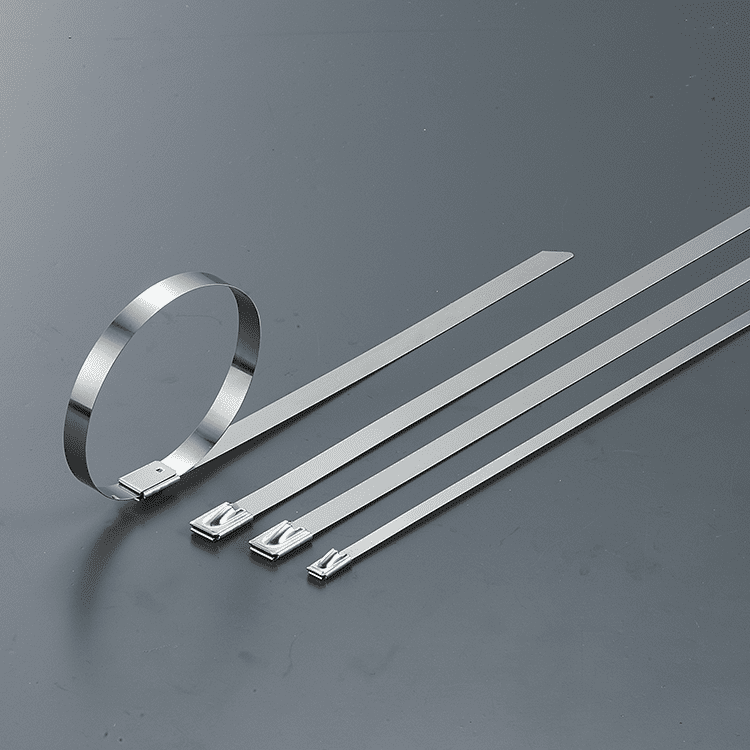

Stainless steel cable ties are widely used in various industries due to their durability, strength and resistance to harsh environments. This blog post will look at the different grades of stainless steel cable ties, their applications, benefits, how they work, how they are used, how they are tightened, how they are cut, and common problems.

Source: BOESE

There are different grades of stainless steel cable ties, each suitable for a specific application scenario:

304 Stainless Steel Cable Ties: Provides good corrosion resistance and is suitable for indoor and general outdoor use. Widely used in construction, automotive and electrical installations.

316 Stainless Steel Cable Ties: Provides excellent corrosion resistance, especially in marine and chemical environments. Suitable for industries exposed to strong chemicals, salt water or extreme temperatures.

201 Stainless Steel: An affordable option with good tensile strength and corrosion resistance for less demanding application scenarios.

Stainless steel cable ties are suitable for a variety of scenarios, including:

Construction: securing cables, pipes and ducts.

Automotive: bundling wires and hoses.

Marine: securing cables and equipment exposed to salt water.

Aerospace: managing cables and components in hot environments.

Industrial: bundling and securing cables in harsh environments.

Stainless steel cable ties offer many significant advantages. First, they have excellent corrosion resistance and can remain stable in harsh environments, making them particularly suitable for use in marine, chemical and underground facilities. Secondly, stainless steel cable ties have extremely high strength and durability and can firmly fix various objects to ensure safety for long-term use. Additionally, they are highly resistant to high temperatures and maintain their physical properties under extreme temperatures without becoming brittle or failing. Easy to install, UV resistant, and suitable for a variety of indoor and outdoor applications. Overall, stainless steel cable ties are a reliable, long-lasting and efficient fastening solution.

Stainless steel cable ties mainly achieve bundling and fixing functions through their structural and material characteristics. They are usually made of high-quality stainless steel, which has the characteristics of high strength, corrosion resistance and high temperature resistance. One end of the cable tie is equipped with a self-locking device. When the other end is inserted, the serrated self-locking buckle will bite tightly and will not be easy to loosen. This design ensures it remains strong even under strong stretching. When using it, just wrap the tie around the object to be fixed, then pass the tie tail through the self-locking head and tighten it.

The method of using stainless steel cable ties is very simple. The following are the detailed steps:

Choose the appropriate cable tie: Choose a stainless steel cable tie of appropriate length and width based on the size of the objects to be tied and the use environment.

Prepare items for bundling: Place items to be bundled neatly together to ensure they do not slip or shift during the bundling process.

Pass through the head of the cable tie: Pass the tail of the stainless steel cable tie through the bayonet of the head of the cable tie to form a loop.

Adjust the tightness: Wrap the zip tie around the items, tightening the zip tie as needed to keep the items securely tied together.

Fix the cable tie: Use a special cable tie tool or manually tighten the cable tie to the appropriate tightness to ensure that the cable tie will not loosen.

Cut off the excess: Use scissors or the cutting function of a zip tie tool to trim away any excess zip tie for a neat look.

To tighten stainless steel ties, follow these steps:

Gather your tools: You’ll need a special zip tie tightening tool. If you don’t have one, you can also use pliers or a wrench.

Thread the cable tie: Pass the cable tie through the object you need to secure, and then pass the tail of the cable tie through the locking hole on the head of the cable tie.

Preliminary tightening: Preliminarily tighten the tie with your hands to ensure that the fixture is in the approximate position.

Use the tool to tighten: Use the cable tie tightening tool, insert the tail of the cable tie, and start tightening. Apply pressure slowly to ensure even force on the tie.

Confirm tightness: After tightening to the required level, make sure the object is securely fastened and not loose.

Cut off excess: Use scissors or the cut function on your tool to trim off excess tie tails for a neat look.

Cutting stainless steel cable ties requires some specialized tools and skills. Here’s a simple step-by-step guide:

Prepare your tools: You’ll need a pair of high-quality cutting pliers or a specialized stainless steel cable tie cutting tool. These tools are usually hard and sharp enough to cut stainless steel.

Positioning the cable tie: Fix the stainless steel cable tie to the area that needs to be cut. Make sure the ties are tight and secure so they don’t slip during cutting.

Cut the tie: Use the cutting tool and position it where you need to cut it. Make sure the tool is aligned with the tie’s cutting point, then cut firmly. Be careful to maintain steady hand strength to prevent accidental slipping while cutting.

Check the cut: After cutting, check whether the cut of the tie is flat. If the cut is uneven, lightly sand it with sandpaper to avoid injury from the sharp edges.

BOESE is a leading high quality ss cable tie manufacturer and is committed to providing excellent products and services to customers worldwide. We specialize in researching, developing, manufacturing and selling various types of stainless steel ties, which are widely used in construction, electric power, transportation, communication and other major fields. BOESE has advanced production equipment and strict quality control system to ensure that each product meets international standards and satisfies the high requirements of customers. We not only provide standard specification cable ties, but also can customize special specifications according to customers’ needs, and strive to perfectly match every application scenario. Choosing BOESE means choosing reliability, durability and professionalism. We will continue to uphold the principle of customer first and keep innovating to protect your projects.

Q1: What are the sizes and models of stainless steel cable ties?

Stainless steel ties come in a variety of sizes and models, often categorized by width, length and thickness. Common widths include 4.6mm, 7.9mm and 12mm, and lengths can range from 100mm to 1200mm. Depending on the application requirements, you can also choose between wrapped and un-wrapped cable ties.

Q2: How to install stainless steel cable ties?

To install stainless steel cable ties, you need to use a special cable tie tool (e.g. cable tie gun). First, pass one end of the tie through the hole in the head of the tie, then tighten it to the desired tightness, and finally use the tool to cut off the excess and make sure the head of the tie is firmly locked.

Q3: Are stainless steel cable ties corrosion resistant?

Yes, stainless steel ties offer excellent corrosion resistance, especially in harsh environmental conditions. They are usually manufactured from 304 or 316 grade stainless steel, which has high corrosion resistance and is suitable for corrosive environments such as marine, chemical and other corrosive environments.

Q4: What is the operating temperature range of stainless steel cable ties?

The operating temperature range of stainless steel ties is typically between -80°C and 538°C. The temperature range of stainless steel ties is typically between -80°C and 538°C. The exact temperature range may vary depending on the grade of stainless steel and the manufacturing process of the tie.

Q5: Are stainless steel cable ties reusable?

Typically, stainless steel ties are designed for single use to ensure maximum safety and strength. Reuse may affect the fastening properties and security of the tie and is therefore not recommended.

Want To Explore More Quality Cable Ties?

Privacy Policy | Sitemap

Copyright BOESE Co.,Ltd SUPPORT BY :JUNJ